TouchPoint HMI

The tech behind the touch

TouchPoint chips power SmartSurface touch interfaces with accuracy and control

UltraSense TouchPoint HMI Controllers fully integrate multi-mode touch sensing, lighting control, and algorithm processing in a single chip – powering a new generation of Human-Machine Interfaces

Fully Integrated Sensor Systems on a Chip

TouchPoint products use a combination of capacitive, ultrasound, and force-sensing technology for a variety of applications

UltraSense TouchPoint C

CapForce HMI Controller

Capacitive + Force integrated System on a Chip (SoC) controller including Analog Front End (AFE)

- Drives and senses single channel Self-Cap capacitive electrode

- Integrated patented QuadForce piezoelectric 4-strain sensor architecture

- Minimum detectable Strain: 0.8uS (microstrain)

- Sensitivity: 25LSB/uS, or 20mV/uS

- Pulse Width Modulator (PWM) control for LED backlighting of icon

- Direct communication with haptic controller for no-latency tactile feedback

- Senses through typical plastic and glass materials up to 5 mm in thickness

- AEC Q100 Grade 2 Qualied (Operating range: -40°C to 105°C)

- 3 mm x 3 mm x 0.6 mm QFN package

CapForce

UltraSense TouchPoint Q

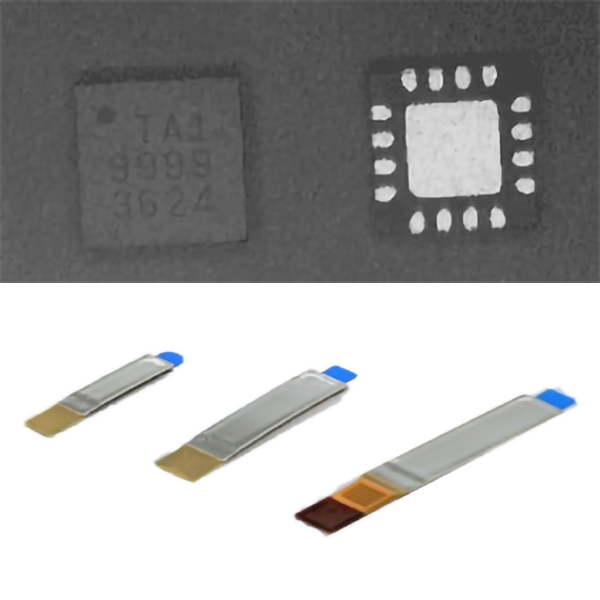

TapForce™ HMI Controller “Force Sensor”

Piezoelectric Force sensing integrated SoC controller including AFE

- Augments existing capacitive systems with force sensing

- One controller senses multiple buttons depending upon system mechanical design

- Mounting substrate can be by traditional PCB or flexible printed flims

- Integrates QuadForce piezoelectric 4-strain sensor architecture

- Minimum detectable Strain: 0.8uS (microstrain)

- Sensitivity: 25LSB/uS, or 20mV/uS

- AEC-Q100 Grade 2 Qualified (Operating range: -40°C to 105°C)

- 3 mm x 3 mm x 0.6 mm QFN pkg (In-Plane) or 2.6 mm x 1.4 mm x 0.5 mm (Z-Pillar)

TapForce

UltraSense TouchPoint Z

UltraForce™ HMI Controller

Ultrasound + Force integrated SoC controller including AFE

- For Touch on Metal applications

- Transmits and receives ultrasound beam through material stacks using an array of Piezoelectric Micromachined Ultrasound Transducers (PMUTs)

- Senses through conductive surface materials (e.g. metals) that capacitive technology cannot

- Detection up to 5mm thickness depending on metal materials

- Integrates patented QuadForce piezoelectric 4-strain sensor architecture

- Minimum detectable Strain: 0.8uS (microstrain)

- Sensitivity: 25LSB/uS, or 20mV/uS

- PWM control for LED backlighting of icon

- Direct communication with haptic controller for no-latency tactile feedback

- AEC-Q100 Grade 2 Qualified (Operating range: -40°C to 105°C)

- 2.6 mm x 1.4 mm x 0.5 mm optical LGA package

UltraForce

A single SmartSurface HMI controller to replace a cluster of mechanical buttons

TouchPoint Edge can be combined with multiple transducers for multi-mode InPlane Sensing

UltraSense TouchPoint Edge

HMI Controller for Multiple Buttons

Centralized SoC integrating 16-channels of touch sensing, MCU, AFE and Neural Touch Engine

- 24-channel (up to) capacitive touch sensing

- 8-channel ultrasound touch sensing

- 8-channel piezo-force sensing

- Auxiliary sensor sensing engine

- Strain Gauge readout AFE

- IR/photodiode readout AFE

- Embedded MCU with propriety sensor-fusion algorithms

- Multiple I/O protocol: I2C Master, I2C slave, UART, LIN, SPI

- 10 GPIOs with PWM capability

- To be used with TouchPoint P (UltraForce) & TouchPoint S (TapForce) transducers

- Operating range: -40°C to 105°C

- 7 mm x 7 mm x 0.6mm QFN package

UltraSense TouchPoint P

UltraForce Transducer

Piezoelectric Ultrasound + Strain sensing transducer

- Operating range: -40C°C to 105°C

- 2.6 mm x 1.4 mm x 0.5 mm LGA package

UltraSense TouchPoint S

TapForce Transducer

Strain-sensing transducer

- Operating range: -40°C to 105°C

- 2.6 mm x 1.4 mm x 0.5 mm LGA package

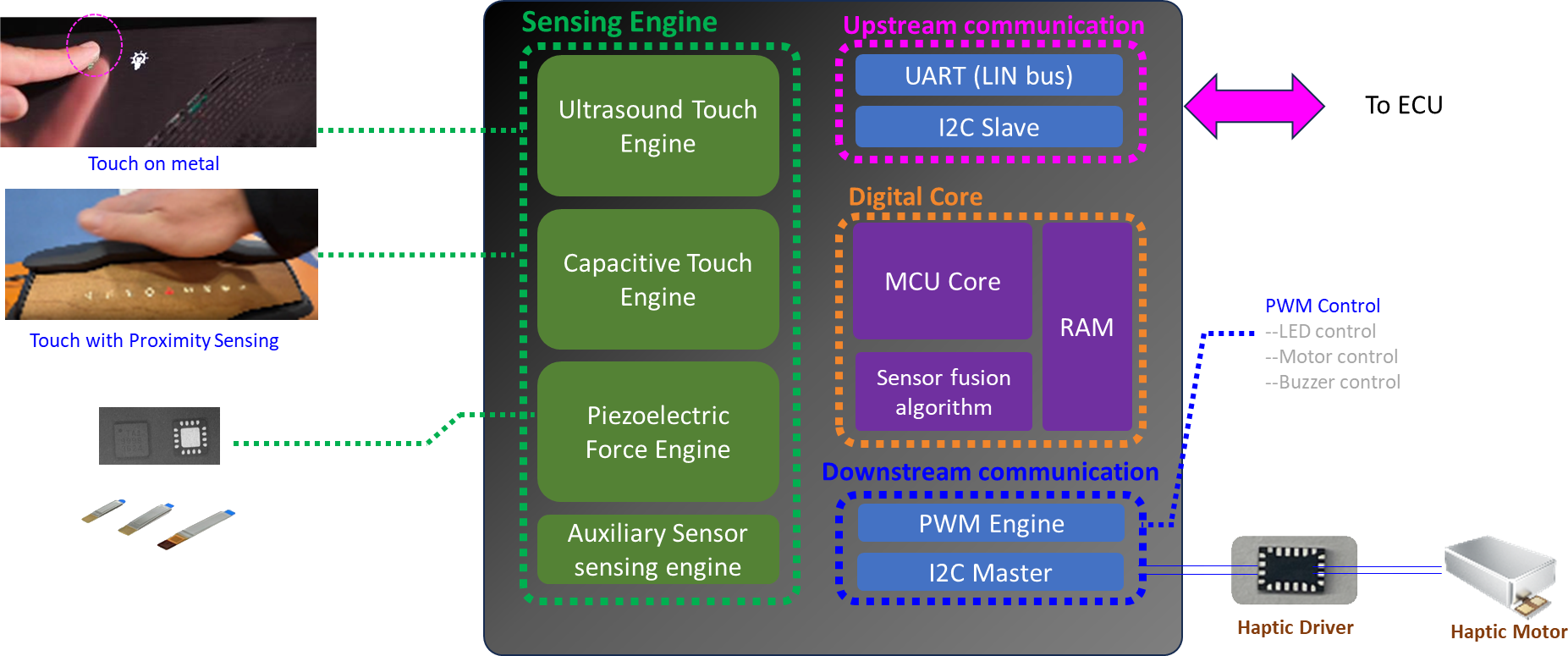

UltraSense TouchPoint Edge

UltraSense TouchPoint Edge

Sensing Engine

Ultrasound Touch Engine

Ultrasound Touch Engine

Touch on metal

Capacitive Touch Engine

Capacitive Touch Engine

Touch with Proximity Sensing

Piezoelectric Force Engine

Piezoelectric Force Engine

Force Sensing

Superior performance under large manufacturing tolerance

Auxiliary Sensor sensing engine

Upstream Communication

UART (LIN bus)

I2C Slave

Upstream Communication

To ECU

Digital Core

MCU Core

Sensor fusion algorithm

RAM

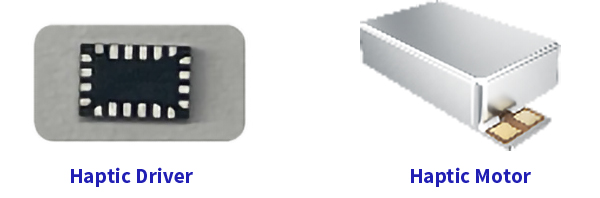

Downstream Communication

PWM Engine

I2C Master

Downstream Communication

PWM Control

- LED control

- Motor control

- Buzzer control

Customization and Control for OEMs and Tier‑Suppliers

Self-tuning & Configurability

AI / Machine Learning algorithms learn intended versus accidental touch and eliminate edge cases

Firmware supports local processing, low power, and configurable frame rate

Feedback Controls & Customization

Easy-to-use UltraStudio 2.0 software allows custom tuning of lighting, audio, and haptics